They’re Here! Why You Need to Embrace 2D Barcodes.

No doubt, five decades is a good run. The use of 1D barcodes for the past 50 years has revolutionized supply chains and retail, but globalization and the need to track and trace goods in real time are exposing some major limitations. From consumer demand for in-depth production information to the growing use of automated systems in warehouses and factories, the need for more robust data printed directly on packaging has never been greater.

Enter 2D barcodes. While a deceptively simple name, 2D barcodes may one day provide a globally recognized and standardized way to enable “improved inventory management, enhanced recall readiness, greater sustainability and ethical sourcing, better product authentication, and greater brand trust,” according to GS1, the standards body for barcodes.

But making the transition from 1D to 2D barcodes across the millions of retailers in the U.S. alone is no easy feat and certainly not one that can happen overnight. To that end, GS1 has established the Sunrise 2027 initiative, which aims to have all retail backend systems and point-of-sale (POS) infrastructures set up to accept 2D barcodes by 2027.

Even with the long runway, it’ll be difficult for manufacturers or retailers and those that support them to make the change by the deadline. But adopting 2D will ultimately lead to long-term gains. For a quick summary, download our 2D barcode infographic or continue reading for the full story.

1D vs. 2D barcodes

1D barcodes consist of roughly two dozen linear, alphanumeric “characters” (lines and spaces). These can hold a very limited amount of data such as basic product and pricing information. 1D barcodes are standardized by the GS1, meaning most retailers around the globe can read and accept them.

But with a limit of 20 characters, 1D barcodes simply lack the data capacity for robust traceability, inventory management or combatting counterfeit items. And if the barcode is distorted in any way, laser scanners may not be able to read it accurately, which can result in discarded or returned goods.

Conversely, 2D barcodes don’t actually have bars! They are created with a “matrix code” – a geometrical design of dots, squares, hexagons or other shapes. Beyond the familiar QR code, there are many more types. Regardless of the exact type, all 2D barcodes can hold far more than simple alphanumeric characters – they can also include references to images, sounds, website details and other consumer or purchasing information. GS1 is working toward standardizing 2D barcodes, but we’re not there yet. Aside from QR codes, other popular formats include data matrix and PDF417 codes just to name a couple.

2D barcodes can hold upwards of 7,000 characters (depending on the format) as information is stored vertically and horizontally. Scanning is improved as a reader can scan from any direction – even on curved or other oddly shaped packaging. Even better, 2D codes can be read by imaging software, which expands capability to mobile phones and other devices. That said, current laser scanners cannot read 2D barcodes, so the entire retail infrastructure must be updated to 2D-capable scanning equipment before a full 2D transition will be possible.

Because of its character limitation, the meaning of a 1D barcode only becomes apparent when a user refers to a backend database. In contrast, 2D barcodes allow organizations to store the most pertinent information directly in the barcode. This makes 2D barcodes ideal for tracking products at any point along the supply chain even without access to the original supplier’s database. Simply stated, products can tell their own story when affixed with a 2D barcode.

2D barcode advantages

Why should you care about any of this? True, 2027 is still a few years away. However, making the switch early means you’ll be a step ahead as the traceability and efficiency game changes for manufacturers and retailers around the world!

In today’s information age, consumers are hungry for information about the products they purchase. With 2D barcodes, producers and retailers can directly engage with their customers, providing key product details. For instance, manufacturers can embed sustainability details, nutritional information, and/or how-to videos their customers can easily access with the camera on their phone.

Similarly, tracking products through every step of the production, shipping, and retail experience becomes far easier. And in the event of a recall, manufacturers can more easily trace their products. The white paper Powering the Future of Retail from GS1 US, notes:

“…sharing richer product data across the retail value chain – data like place of purchase and product purchased – creates opportunities for improved consumer protection through faster and better targeted product recalls. For example, a single barcode symbology that contains information about batch/lot and country of origin would provide an incentive for every stakeholder along the supply chain to capture data to provide greater supply chain visibility.”

This fits in seamlessly with the FDA’s final Food Traceability Rule, which has been established to help identify, trace and prevent or mitigate foodborne illnesses and contamination. Using key data elements (KDEs) at each point in the food production and shipping process, information can be connected via blockchain technology and food can be tracked in a matter of seconds.

Additionally, there’s enhanced inventory management. With the ability to add product names, serial numbers, lot/batch numbers, key dates for shipping and arrival, expiration dates, images and other product details, warehouses can better store, track and ship products. This reduces the worry of errors or lost inventory and increases the ability to quickly and easily update customers on the status of items they have purchased. Having all this information at their fingertips enables companies to make smarter business decisions, optimize warehouse layouts and audit stock.

Preparing for 2D barcode Implementation

Given the many advantages of 2D barcodes, why are 1D barcodes even still around? While switching to a new barcode type may seem relatively simple, the reality is that making the switch will require significant changes to retail and manufacturing infrastructure, and there’s inherent built-in resistance to changing something that works, even in the face of better alternatives. Globally accepted standards for 2D will certainly speed things along – when they are finalized and adopted. Regardless of where you are on the adoption curve, 2D barcodes are undeniably going to replace 1D barcodes in the not-too-far-off future. The time to prepare for this reality is now and doing so will deliver immediate benefits while setting you up for the future.

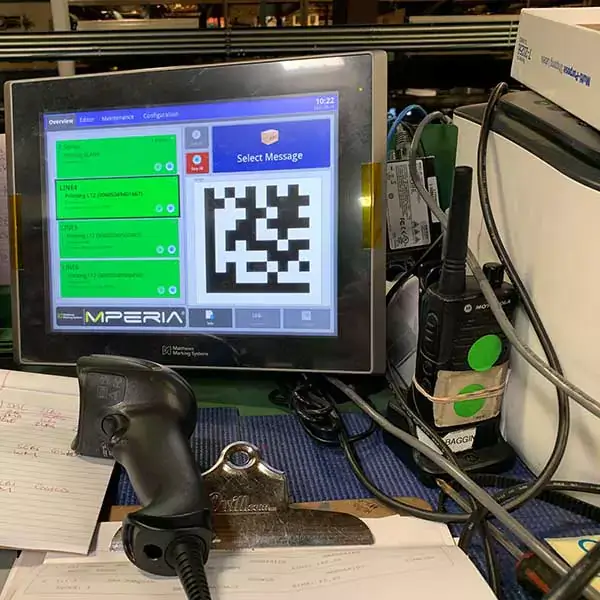

If you’re not sure where to start, or how to explore options for 2D barcode printing for traceability and efficiency initiatives, Matthews is here to help. We’re staying on top of developments from GS1 and already working with customers on 2D marking programs. What’s more, our MPERIA platform includes 2D barcode validation capabilities and can control multiple printer technologies from a single controller. This allows you to match the ideal printing technology with your requirements, which can vary significantly depending on the application.

Contact us at 800.775.7775 or [email protected] — we’d love to chat with you about the future of 2D barcodes and learn more about your plans.