EstiFrame Technologies, A Simpson Strong-Tie Company, integrates Matthews’ MPERIA® OEM Controller and T-Series printheads.

Upgrade to support and enhance the marking precision and mark durability of their EasyFrame saws.

Summary

Launched in 2017, EstiFrame has a lineage that includes 40 years of experience in framing and software development. Founders Aaron Love and Coby Gifford created EstiFrame to deliver products and solutions that make the building process quicker, more efficient, and more precise. Their line of EasyFrame saws — an automated marking and cutting system for preparing lumber — is a central part of making this vision a reality.

To maintain and build on their strong reputation for precision, reliability, and innovation, the EstiFrame team is committed to staying on top of the technologies and developments that make the work easier for their customers. They partnered with Matthews Marking to level up the speed, accuracy, and durability of the marks that tell framers how a structure gets built.

The Challenge

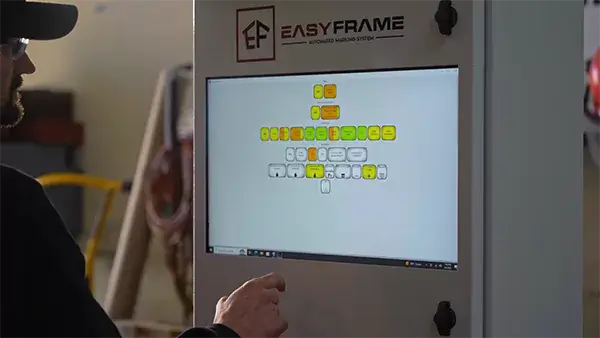

EasyFrame saws are at the heart of EstiFrame’s innovative building solutions. These machines offer builders incredible power, a simple interface, compatibility with all major design platforms, and built-in tools that are fully customizable to each customer’s particular needs.

But their legacy marking solution was causing EstiFrame some serious and consistent performance problems that were jeopardizing customer satisfaction and threatening to tarnish EstiFrame’s strong reputation. Founder and Product Manager, Coby Gifford, explains, “Prior to using the Matthews technology, we were spending a lot of time going back out into the field and dealing with problems that were all pointing back to the printer. Sometimes we’d have failures with the equipment failing right out of the box.”

In addition to issues with mark accuracy and durability, EstiFrame was also battling operational problems due to the high levels of maintenance required by their legacy marking solution. EstiFrame West Coast Manager, Ben Littau, explains the pre-Matthews situation, “I asked all the operators how much time they spent during a shift to maintain the equipment and keep the print consistent. Multiple operators said about an hour-and a-half every eight-hour shift. That was an enormous amount of time in my mind. I figured if it was over 10 minutes there was something wrong.”

The EstiFrame team knew they needed to make a change. They needed a marking solution that could live up to the promise of the EstiFrame brand. As EstiFrame Equipment Sales Manager, Aaron Love, says, “We don’t make excuses. We provide solutions.” They needed a partner with the same mindset and commitment to excellence.

The Solution

EstiFrame now uses Matthews’ MPERIA® OEM controller with MPERIA T-Series high-resolution piezo inkjet printers. This solution provides EstiFrame with the most accurate, high-quality, and durable mark while minimizing maintenance requirements. It also helps them reduce their time to market by removing integration headaches.

The MPERIA OEM controller provides easy XML integration, and is the only universal controller designed to work with any print technology. EstiFrame uses XML to facilitate communication between the MPERIA operating system and EasyFrame’s controller to ensure the accuracy of data being transmitted to print the T-Series’ marks on the various pieces of lumber being cut.

The EstiFrame team was able to get the first Matthews’ demo unit up and running in one day, and they were immediately impressed with the seamless and highly flexible integration.

“It’s an amazing print controller — very streamlined, very sensible,” says Coby, “What we really liked about it was the fact that you can literally manipulate the XML on the controller itself. We were really, really impressed.”

The MPERIA OEM controller and T-Series printer solution also greatly reduced QA and maintenance issues. “We literally haven’t had a system fail in the two years that we’ve been running the Matthews solution,” says Coby.

And Ben has been really pleased with how little maintenance is required. “I have one operator who has gone two months without ever doing a clean cycle. He’s never even taken a swab to the system. He’s never touched it, and he’s gone through an entire bottle of ink and it’s just worked perfectly the entire time. You can’t even do that with a home printer. Especially running it eight, ten, or twelve hours a day.”

Even the Matthews ink — AccuScan Black — makes a difference. “Another advantage that we found with the Matthews is the ink,” says Coby. “We didn’t think the ink could make such a difference. But the Matthews ink is quite a bit better than the inks we had used in the past.”

Crisp, easily readable T-Series marks on lumber enables ultra-efficient framing.

The Results

Since implementing the Matthews MPERIA OEM solution with T-Series printers, the EstiFrame team has experienced improved system performance, reduced maintenance, no system failures, excellent mark accuracy and durability, and — perhaps most importantly — consistently improved customer satisfaction.

Seamless XML integration enables intuitive operation of the EasyFrame saw.

RJP Framing, a provider of prefabricated walls, is just one of EstiFrame’s many happy customers. RJP Production Manager, Oscar Aguirre, has this to say about the EasyFrame system, “The machine’s a great machine — very well made. And the printer is really, really good. The mark is very clear, very accurate, and very durable. There’s never been a case where the markings came off, either by accident or in testing.” The Matthews’ mark withstood RJP Framing’s durability testing, which involved trying to wash the marks off immediately after application. The marks also proved their durability over time after an RJP job was delayed by six months. Although sun and weather aged the lumber over that time period, the marks were still clear and accurate.

Coby sums up EstiFrame’s experience with Matthews this way, “Since we got the Matthews system, for the first time in twelve years, I feel bulletproof with the marking.”

The Video

See the Matthews solution in action, in the video below.

Learn more about marking on building materials in our Marking Technology for Building Products Showdown.

About EstiFrame

In 2017, with over 40 years of experience in framing and software development, Aaron Love and Coby Gifford created EstiFrame Technologies Inc. With this newfound partnership, they designed and built the EasyCut Saw with the intent of being the best in the market advancing the future of the industry. They continue to improve the EasyCut Saw, manufacturing new and improved data-driven machinery with a fully automated layout marking system and the goal to make the process quicker, more efficient, and more precise. EstiFrame Technologies takes pride in their work every step of the way, whether it’s with helping with design, making panelization easier, better optimization, faster cutting, or minimizing waste, EstiFrame is here to make it Easy.