Sweden’s leading snack manufacturer eliminates production line bottlenecks and doubles capacity with Matthew’s MPERIA® A-Series T63 automated pallet labeling system.

Summary

A market-leading Swedish snack manufacturer with almost seventy years of heritage needed to modernize their pallet labeling system with a more accurate, flexible, and efficient solution. Their legacy palletizing system was creating a bottleneck on the production line, which was slowing down their ability to meet shipping and transport deadlines.

The company overcame this challenge by pairing a new palletizing system with Matthews’ MPERIA® A-Series T63 automated pallet labeling system. This solution provided the highest level of efficiency and allowed them to easily label stacked pallets. Overall, the company was able to double production capacity — from 100 to 200 pallets per hour.

The Challenge

The snack manufacturer was having trouble staying on top of shipping deadlines because their existing palletizing and labeling technology was creating substantial production bottlenecks. The line was fairly standard — boxes of product were stacked on pallets, wrapped with film, and then labeled for shipping. Automated guided vehicles transported the completed pallets to the loading area.

The challenge was that the existing system could only handle one pallet at a time, which greatly limited production capacity. The manufacturer needed a flexible, reliable solution that could be easily integrated into the existing production requirement, and which would automate the labeling of stacked pallets.

The Solution

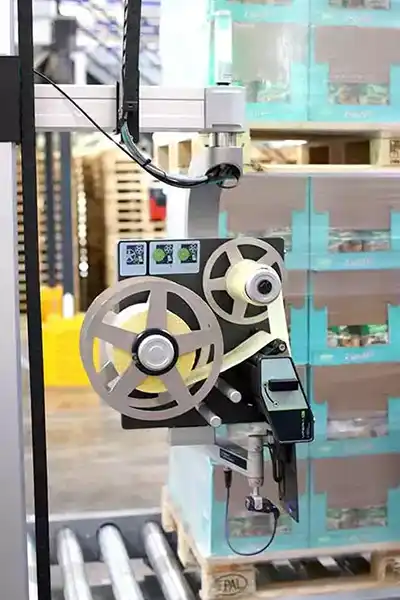

The manufacturer ultimately settled on Matthews Marking Systems’ MPERIA® A-Series T63 automated pallet labeling system with FlexWipe applicator and a motorized stand as the ideal solution. The system’s ability to label stacked pallets combined with its small footprint, emphasis on operator safety, ease of use, seamless integration, and tool-free maintenance made it highly appealing in terms of quality, value, and performance.

Motorized Stand — Provides the Greatest Flexibility in Confined Space

The motorized stand with pneumatic traversing system easily moves the labeler up and down at any height between 29.14” to 84.25” (740 mm to 2140 mm). It also has a special sensor that enables precise label placement on pallets of different heights. In addition, the arm of the FlexWipe applicator rotates flexibly around several axis, which means the entire system requires less than 3.3ft² (1 m²) of floor space, making it easy to integrate even in tight spaces.

MPERIA A-Series T63 with FlexWipe

Applicator

A-Series T63 labeling stacked pallets

Stacked pallets with labels applied to

two sides

Intelligent Safety Equipment — Eliminates the Need for Bulky Cages or Bolt-on Protection

Safety is engineered into the A-Series design. Intelligent sensor technology in the Flexwipe applicator and motorized stand guarantee operator safety with automatic shut-down and retraction. These features eliminate the need for any protective enclosure on either the motorized stand or the labeling system.

Intuitive User Interface — Simplifies Image Management and System Control

The color touchscreen user interface for controlling the MPERIA® A-Series is simple and intuitive. Operators can easily make adjustments to the print image in just a few simple steps, and control is possible via either the MPERIA® controller or remotely. The MPERIA® controller also easily integrates with other marking technology and peripheral devices.

Automatic Code Validation — Streamlines Production by Combining Print, Apply, and Validate in one System

The A-Series automated print-and-apply labeling system prints labels up to a DIN A5 format in either landscape or portrait mode, and is fully compliant with GS1 pallet labeling standards. Its FlexWipe applicator prints and applies the labels, and then the system validates the label readability via an integrated camera on the back of the applicator pad. In the event of any inconsistencies, the system immediately alerts the operator, avoiding costly rework.

The Results

By switching from its existing palletizing and labeling technology to handling stacked pallets with Matthews’ MPERIA® A-Series, the snack manufacturer was able to safely and efficiently achieve peak productivity and completely eliminate the previous palletizing bottlenecks. The new Matthews’ system doubled their labeling capacity from 100 pallets per hour to 200 pallets per hour.

The company is very happy with this outcome and with the overall performance and reliability of the fully automated labeling solution from Matthews Marking Systems. The MPERIA® A-Series not only resolved their initial challenge, it continues to ensure reliable operation, precise printing and placement, maximum safety, easy maintenance, and impressive longevity. All of these benefits help improve operations at their facility, keep up with demand for their products, and deliver a better customer experience.